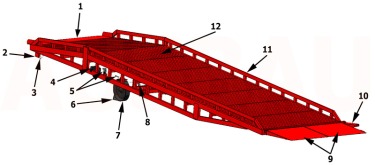

Mobile ramp (mobile loading ramp) AUSBAU – metal construction in the form of an inclined platform, which balances out the difference between ground/warehouse surface and truck body. It significantly speeds up unloading and loading processes in the warehouse.

CE Standard.

Mobile loading ramp allow you to significantly speed up the process of goods loading and unloading at the warehouse. Unlike stationary dock ramps, you can freely move them around the warehouse and far beyond with the help of the built-in transport base, which is a significant advantage.

Our company has a variety of mobile ramp models, with a load capacity of 6, 8, 10 and 12 tons. Besides, we can create a customized loading ramp of any load capacity. Low price and high quality are the distinctive features of our products.

| Load capacity, kg | 6000 / 8000 / 10000 / 12000 |

| Total length, mm | 9000 / 9500 / 10500 / 11200 / 12000 / 13000 |

| Total width, mm | 2220 / 2260 / 2300 / 2340 |

| Usable width, mm | 2000 |

| Length of inclined part, mm | 8000 / 8500 / 9200 / 9900 |

| Connecting lip length, mm | 300 |

| Min. working height, mm | 900 |

| Max. working height, mm | 1750 |

| Height of the safety railings, mm | 180 |

| Number of folding bridges, pcs | 2 |

| Number of wheels, pcs | 2 |

| Wheels | solid rubber |

| Material | S235 |

| Driving surface | zinc-coated anti-skid grating |

| Components | rubber wheel chocks – 2 pcs, tow pole – 1 pc, set of chains on the ramp – 7 pcs, manual hydraulic pump with handle – 1 pc. |

| Warranty | 18 months |

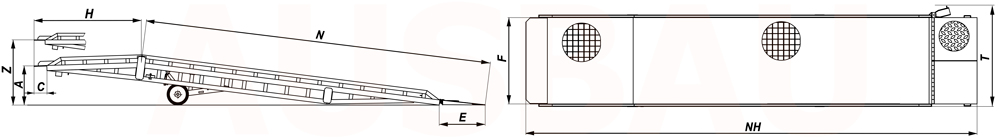

| # | Model | Load capacity, kg | Ramp size, mm | ||||||||

| N | H | E | C | NH | F | T | A | Z | |||

| 1 | PRO6 | 6000 | 8000 | 2500 | 1000 | 300 | 10500 | 2000 | 2220 | 900 | 1650 |

| 2 | PRO8 | 8000 | 8000 | 2500 | 1000 | 300 | 10500 | 2000 | 2260 | 900 | 1650 |

| 3 | PRO10 | 10000 | 8500 | 2700 | 1000 | 300 | 11200 | 2000 | 2300 | 900 | 1650 |

| 4 | PRO12 | 12000 | 8500 | 2700 | 1000 | 300 | 11200 | 2000 | 2340 | 900 | 1650 |

| 5 | SRT6 | 6000 | 8000 | 1000 | 1000 | 300 | 9000 | 2000 | 2220 | 900 | 1550 |

| 6 | SRT8 | 8000 | 8000 | 1000 | 1000 | 300 | 9000 | 2000 | 2260 | 900 | 1550 |

| 7 | SRT10 | 10000 | 8500 | 1000 | 1000 | 300 | 9500 | 2000 | 2300 | 900 | 1570 |

| 8 | SRT12 | 12000 | 8500 | 1000 | 1000 | 300 | 9500 | 2000 | 2340 | 900 | 1570 |

| 9 | LNG6 | 6000 | 9200 | 2800 | 1000 | 300 | 12000 | 2000 | 2220 | 900 | 1700 |

| 10 | LNG8 | 8000 | 9200 | 2800 | 1000 | 300 | 12000 | 2000 | 2260 | 900 | 1700 |

| 11 | LNG10 | 10000 | 9900 | 3100 | 1000 | 300 | 13000 | 2000 | 2300 | 900 | 1750 |

| 12 | LNG12 | 12000 | 9900 | 3100 | 1000 | 300 | 13000 | 2000 | 2340 | 900 | 1750 |

The forklift lifts the edge of the ramp (there is a special place for a rigid coupling grasp) and brings it to the truck. Using manual hydraulics, one person presses the hydraulic pump handle and sets the required height of the ramp (from 900 mm to 1,650 mm).

After installation, the mobile loading ramp is securely fastened to the truck with two chains, and the wheels are fixed by chocks (chains and wheel chocks come complete with a ramp). Then the loaded forklift comes up the mobile ramp and goes directly into the truck or container.

Thus, one forklift driver is enough to carry out all loading and unloading operations. So you don’t need the worker who used to pull the loads with a trolley from/to the edge of the truck.

As a result, our mobile loading ramp significantly speeds up the loading and unloading processes, saves labor costs, optimizes logistic processes and increases profits.