Many companies employ electro-hydraulic leveling platforms (dock levelers) AUSBAU-DL to compensate for the difference in height between the level of a concrete ramp and a truck body during loading and unloading. By means of such warehouse equipment, the issue of access of loading equipment to a truck body is solved. The hydraulic dock leveler covers the space between the truck body, which allows loading and unloading operations in a shorter time. Such equipment is indispensable in transport logistics.

| Maximum load capacity | 10000 kg |

| Maximum platform width | 2000 mm |

| Maximum platform length | 2500 mm |

| Number of hydraulic cylinders | 2 pcs |

| Supply voltage | 380 V |

| Maximum operating temperature | 50° С |

| Minimum operating temperature | -40° С; |

| Own weight | 800 kg |

| Warranty | 12 months |

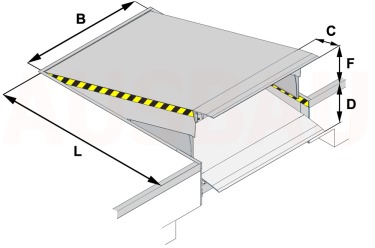

| # | Model | Load, kg | Sizes, mm | Power, kWt | ||||

| L | B | С | F | D | ||||

| D1 | DL-6000-2300×1800 | 6000 | 2300 | 1800 | 400 | 450 | 400 | 1 |

| D2 | DL-8000-2300×1800 | 8000 | 2300 | 1800 | 400 | 450 | 400 | 1 |

| D3 | DL-6000-2500×2000 | 6000 | 2500 | 2000 | 400 | 450 | 400 | 1 |

| D4 | DL-8000-2500×2000 | 8000 | 2500 | 2000 | 400 | 450 | 400 | 1 |

| D5 | DL-10000-2500×2000 | 10000 | 2500 | 2000 | 400 | 450 | 400 | 1 |

Dock leveler AUSBAU-DL consists of a lower support frame that supports all other elements mounted on it. The upper platform is attached to the rear part of the support frame and provides the necessary inclination level. At the front of the dock leveler, there is a turning ramp that provides a connection between the platform and the floor of the truck body. The platform is controlled by a hydraulic drive mechanism by means of a control panel.

The dock leveler is designed to provide a dynamic load of 6 tons and a static load of up to 10 tons.

Components of an electro-hydraulic leveling platform:

The support carcass of the frame on which the moving part and the hydraulic complex are mounted. It is made of laminated profiles and provides accommodation and support for a turning ramp (in the case when the leveling platform is closed or in a resting state).

The platform is equipped with moving side walls and a safety support rack. It’s made of 5 /7 mm diamond steel plate and has strong support from laminated profiles placed under it.

The turning ramp provides a binding of the platform level to a truck body. It’s made of a steel diamond sheet 13/15 mm, milled at the edges.

The hydraulics set consists of an electric motor 1.5 kW, 380 V, 50 Hz at 3000 turnovers per minute and a hydraulic pump with a feed of 5 liters per minute. With an expansion tank of 7 liters and 24V electric safety distributor.

The electrical equipment is equipped with a control panel (24 V), where the components of protection, capacity, and control are located.

CE Standard.